-

Tangki Kaca Yang Dilelehkan Ke Baja (465)

-

Tangki Baja Tidak Berlemak (434)

-

Tangki epoxy yang terikat dengan fusi (469)

-

Tangki Baja Galvanis (321)

-

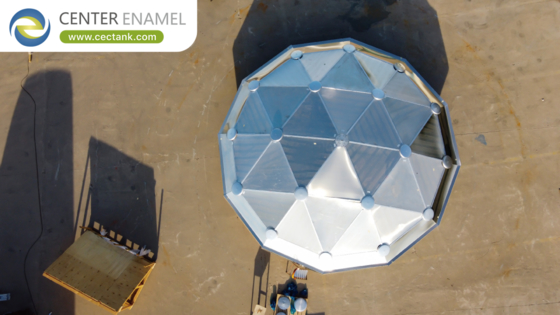

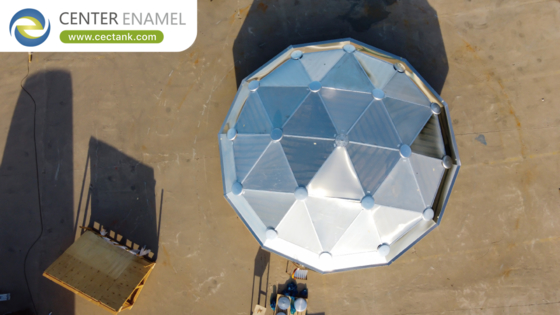

Atap Dome Aluminium (1257)

-

Tangki penyimpanan air limbah (226)

-

tangki baja las (457)

-

Kapal Tekanan (295)

-

Pencernaan Anaerobik (201)

-

Tangki Air Industri (349)

-

Tangki baja berlapis kaca (180)

-

Tangki Baja Berbolt (270)

-

Tangki Penyimpanan Lumpur (115)

-

Tangki Penyimpanan Biogas (173)

-

Tangki Penyimpanan Leachate (133)

-

Tangki penyimpanan air pertanian (179)

-

Tangki Air Api (166)

-

Silos Gudang Gandum (146)

-

Proyek Biogas (381)

-

Proyek Pengolahan Air Limbah (270)

-

Atap Membran Ganda (223)

|

Informasi detil |

|||

Deskripsi Produk

Atap Terapung untuk Tangki Minyak Slop: Mengelola minyak limbah yang mudah menguap dengan aman

Dalam operasi industri dan penyulingan, pengelolaan minyak slop—campuran kompleks dari minyak limbah, air, dan sedimen—adalah tantangan kritis. Aliran limbah yang mudah menguap ini dapat mengandung berbagai fraksi minyak bumi, membuatnya rentan terhadap emisi uap yang signifikan, risiko kebakaran, dan bahaya lingkungan. Penyimpanan yang efektif bukan hanya masalah keselamatan dan kepatuhan lingkungan, tetapi juga langkah menuju potensi pengolahan ulang dan pemulihan sumber daya. Untuk mengatasi masalah ini, tangki atap terapung telah menjadi solusi ideal. Dengan menciptakan penghalang yang tidak dapat ditembus antara minyak slop yang mudah menguap dan atmosfer, tangki-tangki ini secara efektif mengendalikan emisi uap, mengurangi risiko kebakaran, dan menyediakan metode yang aman dan bertanggung jawab untuk penahanan sementara. Tangki atap terapung adalah contoh kuat tentang bagaimana rekayasa khusus secara langsung berkontribusi pada keselamatan industri, perlindungan lingkungan, dan ekonomi sirkular.

Fitur dan Keunggulan Produk

Konsep di balik tangki atap terapung adalah untuk menghilangkan ruang uap berbahaya yang ada dalam tangki atap tetap konvensional. Atap terapung adalah struktur fisik yang terletak langsung di permukaan cairan yang disimpan. Saat permukaan cairan dalam tangki naik atau turun, atap bergerak bersamanya. Desain ini mencegah minyak slop yang mudah menguap bersentuhan langsung dengan atmosfer, yang sangat penting untuk mencegah pelepasan uap dan masuknya kontaminan.

Teknologi ini menawarkan beberapa keunggulan utama untuk penyimpanan minyak slop:

Pengendalian Uap yang Efektif: Dengan menghilangkan ruang uap, atap terapung secara signifikan mengurangi emisi senyawa organik volatil (VOC) dan uap berbahaya lainnya, membantu fasilitas mematuhi peraturan lingkungan dan mengurangi risiko bau dan kesehatan.

Mengurangi Risiko Kebakaran: Tidak adanya ruang uap yang besar berarti tidak ada campuran uap-udara yang mudah terbakar untuk menyala, memberikan lapisan keselamatan dan mitigasi risiko yang penting terhadap kebakaran dan ledakan, yang merupakan perhatian signifikan dengan produk limbah yang mudah menguap.

Mencegah Kontaminasi: Atap terapung bertindak sebagai penghalang yang kuat terhadap kontaminan eksternal seperti debu, kelembaban, dan puing-puing. Hal ini sangat penting untuk minyak slop, karena mencegah kontaminasi lebih lanjut menyederhanakan upaya pemisahan dan pengolahan ulang, meningkatkan nilai ekonomi minyak yang dipulihkan.

Meminimalkan Kehilangan Produk: Bahkan dalam aliran limbah, komponen volatil dari minyak slop memiliki nilai. Atap terapung mencegah kehilangan ini, yang dapat berkontribusi pada kelangsungan ekonomi secara keseluruhan dari upaya pengolahan ulang.

Aplikasi Produk

Tangki atap terapung sangat serbaguna dan menemukan berbagai aplikasi di sektor minyak bumi dan industri. Mereka adalah pilihan yang disukai untuk menyimpan cairan yang mudah menguap di mana pengendalian emisi dan memastikan kemurnian produk sangat penting. Mereka banyak digunakan untuk:

Tangki Minyak Slop: Dirancang untuk kilang dan pabrik petrokimia untuk mengelola dan menampung berbagai aliran minyak limbah yang mudah menguap dengan aman sebelum dapat diproses atau dibuang.

Tangki Minyak Limbah: Digunakan di berbagai pengaturan industri untuk menyimpan berbagai jenis minyak limbah yang mudah menguap yang perlu ditampung dengan aman dan disiapkan untuk daur ulang atau pembuangan.

Tangki Minyak di Atas Tanah: Digunakan di terminal dan pusat distribusi untuk menyimpan berbagai macam minyak dan pelumas, di mana desain atap terapung meningkatkan keselamatan dan mengurangi emisi.

Produk Minyak Bumi Olahan: Teknologi penting untuk menyimpan produk seperti solar, bensin, dan bahan bakar jet, di mana atap terapung mencegah penguapan dan kontaminasi, menjaga kualitasnya.

Keunggulan Perusahaan

Center Enamel adalah pemimpin yang diakui dalam industri tangki penyimpanan. Komitmen kami terhadap kualitas ditegaskan oleh proses manufaktur yang ketat yang mematuhi standar internasional, termasuk ISO 9001 dan EN1090. Tim R&D kami yang berdedikasi terus berinovasi untuk memajukan teknologi, memastikan tangki kami tetap menjadi yang terdepan dalam industri. Kami menawarkan "Layanan Rantai Penuh" yang memandu setiap klien dari konsultasi rekayasa awal dan desain khusus hingga instalasi di lokasi yang efisien dan dukungan purna jual global. Pendekatan terpadu ini menjamin pengalaman proyek yang mulus dan produk akhir yang tahan lama dan berkinerja tinggi.

Studi Kasus Perusahaan

Studi kasus berikut mengilustrasikan kemampuan teknis Center Enamel dan pengalaman proyek yang beragam. Meskipun teknologi untuk proyek-proyek khusus ini berbeda dari tangki atap terapung yang dibahas, mereka menunjukkan keahlian perusahaan yang luas dalam menyediakan solusi penahanan khusus untuk berbagai aplikasi industri dan lingkungan.

Kasus 1: Rekayasa Biogas di Provinsi Shandong

Di Shandong, fasilitas biogas baru dikembangkan untuk mengubah limbah pertanian menjadi energi. Proyek ini membutuhkan solusi penahanan yang dapat menahan sifat korosif dari isi pencerna dan menyediakan lingkungan yang stabil dan kedap udara. Tim memilih tangki Glass-Fused-to-Steel karena ketahanan mereka yang luar biasa terhadap serangan kimia dan desain modular mereka. Tangki-tangki ini sejak itu telah menyediakan solusi penahanan yang andal, memungkinkan pabrik untuk menghasilkan pasokan biogas yang konsisten dan mengelola limbah secara efektif.

Kasus 2: Pengolahan Limbah Makanan di Turki

Fasilitas pengolahan limbah makanan internasional di Turki membutuhkan solusi penyimpanan yang dapat menahan lingkungan yang menantang dan menyediakan segel yang kuat untuk proses pencernaan anaerobik mereka. Pengembang proyek memilih tangki Glass-Fused-to-Steel, yang dihargai karena daya tahan dan sifat kedap udara yang unggul. Konstruksi modular sangat bermanfaat, memungkinkan tangki dipasang secara efisien. Proyek yang sukses ini menunjukkan penerapan global teknologi perusahaan dan kemampuannya untuk berkinerja andal di lingkungan yang beragam dan menuntut.

Kasus 3: Pengolahan Air Limbah Industri di Ethiopia

Taman industri tekstil yang luas di Ethiopia membutuhkan solusi pengolahan air limbah skala besar. Proyek ini membutuhkan sistem penahanan yang dapat menahan sifat korosif dari pewarna dan bahan kimia tekstil. Tim proyek memilih tangki Glass-Fused-to-Steel karena ketahanan korosi yang unggul dan daya tahan yang terbukti. Tangki dipasang dan ditugaskan dengan cepat, membentuk komponen pusat dari pabrik pengolahan yang sangat efisien yang sekarang membantu taman industri memenuhi standar lingkungan.

Kesimpulan

Tangki atap terapung berdiri sebagai komponen yang sangat diperlukan dari penyimpanan minyak slop modern. Kemampuannya untuk mengelola uap yang mudah menguap, mencegah kontaminasi, dan meningkatkan keselamatan menjadikannya solusi unggul untuk mengelola produk sampingan industri ini. Dengan menyediakan penghalang yang andal terhadap paparan atmosfer, atap terapung memastikan bahwa minyak limbah dapat disimpan dengan aman dan bertanggung jawab untuk pengolahan ulang, sehingga mendukung praktik industri yang berkelanjutan. Karena industri terus memprioritaskan tanggung jawab lingkungan dan keunggulan operasional, permintaan akan solusi penahanan berkinerja tinggi seperti tangki atap terapung hanya akan terus meningkat.